Research and Development

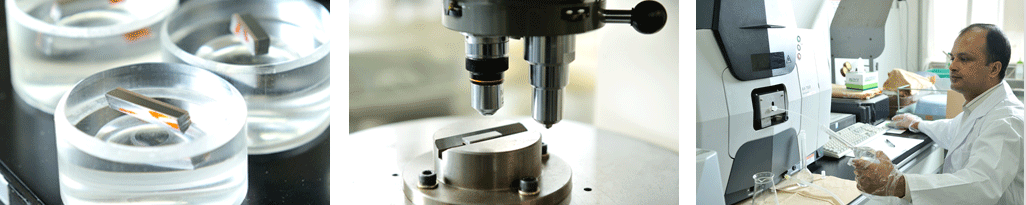

Although a plain bearing looks like a mere cylinder or a metal split into two piece at a glance, its manufacture requires a numerous technologies and experiences in areas such as accuracy of the shape, composition of the alloy to be casted over the surface, thickness, plating, etc. High quality bearings can be realized once various conditions, such as, needless to say, accurate shape adjusted to the engine, each ratio in the composite material, casted volume of the alloy, back-metal temperature, rotation speed and cooling time for centrifugal casting, stress release and the like, are cleared. Through its long history, Isoda Metal has accumulated outputs of research and development to complete highly reliable bearings. The Company started research on the overlay plating from the early stage. As a result, it successfully materialized this technology used for bearings first in the industry. It is now adopted as a standard technology and is applied to a numerous number of bearings. As for the alloy to be casted to the inner side of bearings, we have developed the original metal in pursuit of the optimal conditions. Thus, we have concentrated our power into research and development in order to provide bearings of better quality. Moreover, in aspects of casting, fabrication and plating processes, we now can manufacture our products in the optimal conditions based on massive data that have been accumulated for a long period. In the world of marine engines that are to be used for tens of years, it is important that the reliability is well established. The overlay plating technology and our original alloy were finally materialized as a result we had repeated a number of experiments and tests until such technologies are introduced into the actual products. Among others, in R&D of bearings for the marine engine applications, establishment of reliability is most important in order to ensure safe navigations. We at Isoda Metal are striving daily towards development of further reliable technologies and materials.