product

03 Bearing Structure and Composition Table

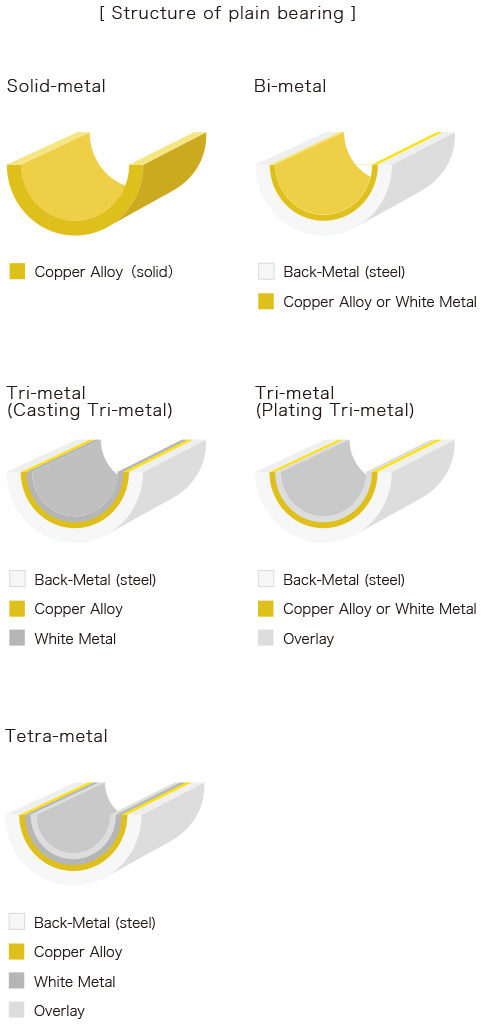

Isoda Metal’s bearings are made of multilayer structure and the copper alloys and white metal are used on the inner surface. We provide the optimum bearing applications and engines used site.

White metal (babbit metal)

| Standards | Chemical composition(%) | Mechanical properties | ||||||

|---|---|---|---|---|---|---|---|---|

| Symbol | Sn | Sb | Cu | Cd | Others | tensilestrength(N/mm2) | Elongation(%) | Hardness(BHN) |

| JIS WJ1 | rest | 5.0~7.0 | 3.0~5.0 | ― | ― | ≧74 | ≧14.0 | 24 |

| JIS WJ2 | rest | 8.0~10.0 | 5.0~6.0 | ― | ― | ≧85 | ≧8.0 | 27 |

| ISD 11XXS | rest | 6.0~8.0 | 2.5~5.0 | 0.5~1.5 | Te,Co | ≧89 | ≧17.0 | 29 |

Copper-lead alloy (kelmet)

| Standards | Chemical composition(%) | Mechanical properties | ||||||

|---|---|---|---|---|---|---|---|---|

| Symbol | Cu | Pb | Sn | Ni | Fe | tensilestrength(N/mm2) | Elongation(%) | Hardness(VHN) |

| Old JIS KJ3 | rest | 28.0~32.0 | ≦1.0 | ≦2.0 | ≦0.8 | ≧79 | ≧6.0 | ≦40 |

| Old JIS KJ4 | rest | 23.0~27.0 | ≦1.0 | ≦2.0 | ≦0.8 | ≧118 | ≧7.0 | ≦45 |

Lead-bronze alloy

| Standards | Chemical composition(%) | Mechanical properties | ||||||

|---|---|---|---|---|---|---|---|---|

| Symbol | Cu | Pb | Sn | Ni | Fe | tensilestrength(N/mm2) | Elongation(%) | Hardness(BHN) |

| JIS CAC603(LBC3) | 77.0~81.0 | 9.0~11.0 | 9.0~11.0 | ≦1.0 | ≦0.3 | ≧175 | ≧7.0 | ≧60 |

| JIS CAC604(LBC4) | 74.0~78.0 | 14.0~16.0 | 7.0~9.0 | ≦1.0 | ≦0.3 | ≧165 | ≧5.0 | ≧55 |

| JIS CAC605(LBC5) | 70.0~76.0 | 16.0~22.0 | 6.0~8.0 | ≦1.0 | ≦0.3 | ≧145 | ≧5.0 | ≧45 |

| DIN G-SnPbBz22 | rest | 18.0~25.0 | 2.0~5.0 | ≦2.0 | ≦0.7 | ≧147 | ≧8.0 | ≦70(VHN) |

| ISD ISK222 | rest | 20.0~24.0 | 1.0~3.0 | ≦1.0 | ≦0.7 | ≧147 | ≧8.0 | ≦70(VHN) |

Bronze alloy

| Standards | Chemical composition(%) | Mechanical properties | ||||||

|---|---|---|---|---|---|---|---|---|

| Symbol | Cu | Sn | Zn | Pb | Fe | tensilestrength(N/mm2) | Elongation(%) | |

| JIS CAC403(BC3) | 86.5~89.5 | 9.0~11.0 | 1.0~3.0 | ≦1.0 | ≦0.2 | ≧245 | ≧15.0 | |

| JIS CAC406(BC6) | 83.0~87.0 | 4.0~6.0 | 4.0~6.0 | 4.0~6.0 | ≦0.3 | ≧195 | ≧15.0 | |

Surface plating (overlay)

| Standards | Chemical composition(%) | Mechanical properties | ||||||

|---|---|---|---|---|---|---|---|---|

| Symbol | Pb | Sn | Cu | Ni | tensilestrength(N/mm2) | Elongation(%) | Hardness(MHv) | |

| ISD PL10(PbSn) | rest | 7.0~13.0 | ― | ― | 6~8 | |||

| ISD PL102(PbSnCu) | rest | 7.0~13.0 | 1.0~3.0 | ― | 10~13 | |||

| Nickel Dam | ― | ― | ― | 100 | ||||

| Sn Flash | ― | 100 | ― | ― | ||||

| Pb-Sn Flash | rest | 7.0~13.0 | ― | ― | ||||

| Copper Strike | ― | ― | 100 | ― | ||||

Back-metal (steel)

| Standards | Chemical composition(%) | Mechanical properties | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Symbol | C | Si | Mn | P | S | Yielding point(N/mm2) | tensilestrength(N/mm2) | Elongation(%) | Hardness(BHN) |

| JIS S10C | 0.08~0.13 | 0.15~0.35 | 0.30~0.60 | ≦0.030 | ≦0.035 | ≧206 | ≧314 | ≧33 | 109~156 |

| JIS S12C | 0.10~0.15 | 0.15~0.35 | 0.30~0.60 | ≦0.030 | ≦0.035 | ≧235 | ≧373 | ≧30 | 111~167 |

| JIS S15C | 0.13~0.18 | 0.15~0.35 | 0.30~0.60 | ≦0.030 | ≦0.035 | ≧235 | ≧373 | ≧30 | 111~167 |

| JIS S20C | 0.18~0.23 | 0.15~0.35 | 0.30~0.60 | ≦0.030 | ≦0.035 | ≧245 | ≧402 | ≧28 | 116~174 |

| JIS S25C | 0.22~0.28 | 0.15~0.35 | 0.30~0.60 | ≦0.030 | ≦0.035 | ≧265 | ≧441 | ≧27 | 123~183 |

| JIS S35C | 0.32~0.38 | 0.15~0.35 | 0.60~0.90 | ≦0.030 | ≦0.035 | ≧304 | ≧510 | ≧23 | 149~207 |

| JIS S45C | 0.42~0.48 | 0.15~0.35 | 0.60~0.90 | ≦0.030 | ≦0.035 | ≧343 | ≧569 | ≧20 | 167~229 |

| JIS STKM11A | ≦0.12 | ≦0.35 | ≦0.60 | ≦0.040 | ≦0.040 | ― | ≧290 | ≧35 | |

| JIS STKM13A | ≦0.25 | ≦0.35 | 0.30~0.90 | ≦0.040 | ≦0.040 | ≧215 | ≧370 | ≧30 | |

| JIS SS400 | ― | ― | ― | ≦0.050 | ≦0.050 | ≧235 | 400~510 | ≧24 | |

| JIS SPCC | ≦0.15 | ― | ≦0.60 | ≦0.100 | ≦0.035 | ― | ― | ― | |